At Porex Filtration Group, we are a global leader in porous plastics technology, dedicated to providing innovative solutions that enhance product performance and improve the lives of people around the world. With decades of experience and a relentless commitment to excellence, we have established ourselves as trusted partners in the plastics industry, offering a comprehensive range of products...

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Plastic-Craft® Products, our business is plastics. We have an extensive inventory of plastic materials to suit your needs, and also maintain a complete machine shop to fabricate plastic parts to your specifications. Let us meet your plastics requirements. We have over 50 years of service behind us. We are always available to discuss the application of our service to your unique operation.

Atlas Fibre is a supplier of stock thermoset shapes in sheet, rod and tube in the following grades: G3, G5, G7, G9, G10, G11, FR4 and canvas, linen and paper phenolic. All materials are Mil-Spec and NEMA certified. We also have extensive CNC milling and turning capabilities; CNC sawing, sanding, and material fabrication for all thermoset materials. We can also machine and fabricate all types of...

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Boedeker Plastics stocks the widest variety of engineering and industrial plastics in the industry. The people of Boedeker have the unique knowledge necessary to take customer service a step beyond others in the field providing in-house engineering assistance. Whether you need ten miles or ten inches, Boedeker Plastics has all of your plastic materials, sheets, rods, tubes and custom components.

Send Requests For Quote to Multiple Polyethylene Manufacturers Suppliers Near You

Provide your project details, and we'll connect you to 5-20 qualified Polyethylene Manufacturers companies in your region. 100% free.

Get InformationManually Sourcing U.S./Canadian Manufacturers for 20+ Years

More Polyethylene Manufacturers

This particular polymer is synthesized from long chains of ethylene monomers that are composed of carbon and hydrogen and form double covalent bonds in a number of structural configurations. Because it is available in many forms, polyethylene is the most commonly used plastic.

Annual production rates for this plastic alone are approximately eighty million metric tons. Such a large number is necessary to accommodate the incredible diversity of objects made from polyethylene. Polyethylene manufacturers fabricate bottles, packaging sheets, shower curtains, pipes, wire insulation, plastic bags and containers, bulletproof vests, artificial knees and hip replacement components, flooring, storage and more.

Resistant to water, acids, alkalis, solvents and chemical corrosion, polyethylene is popular in automotive, packaging, transport, medical, pharmaceutical, food and chemical processing, entertainment and electronics industries, to name a few. While this plastic is non-biodegradable, it is recyclable; it can be melted, remolded and rehardened numerous times. Additionally, researchers have been developing new techniques aimed at synthesizing polyethylene from components found in sugarcane in order to create bioplastics.

While bioplastics continue to be studied, most polyethylene is synthesized from ethylene, though several different methods for this are possible. Radical polymerization, anionic addition polymerization, ion coordination polymerization and cationic polymerization are all used in the production of polyethylene through heat and pressurization.

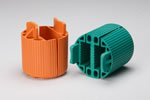

As each process results in a slightly different type of polyethylene, the plastics are classified based on density and branching or crystallization. The three main categories are high-density polyethylene, which has a melting point in the range of 120 to 130°C, low-density polyethylene, which melts at around 115°C, and finally medium-density polyethylene. In total there are ten different divisions including ultra high density and very low density, but the main three will often suffice.

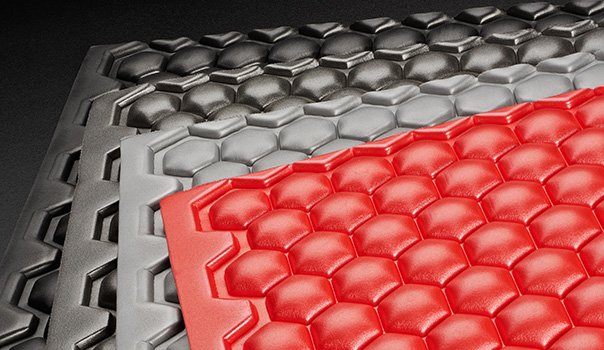

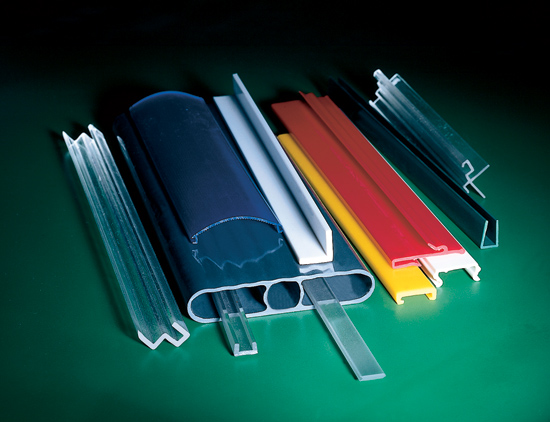

Polyethylene manufacturers utilize these polymer resins forming them into plastic rods, sheets and films through injection molding, casting and extrusion. While stock forms such as these may sometimes be used as the finished product, most will undergo additional operations. Secondary processes employed on plastic materials such as these include drilling, welding, fastening, turning, milling and precision machining. It is important to consider both the manufacturing processes and finish product when selecting a polymer.

Die Cutting

Die Cutting Foam Fabricating

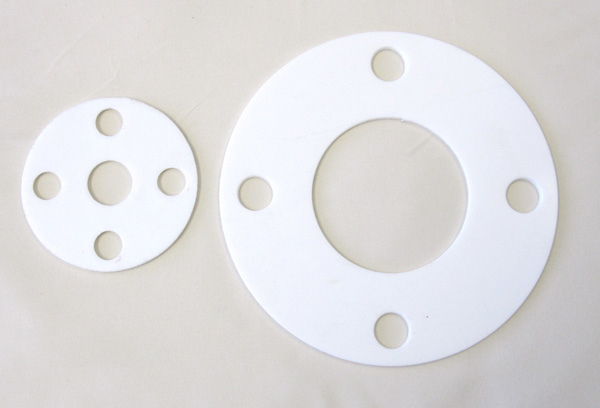

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

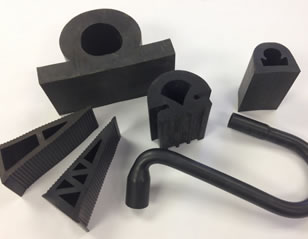

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services