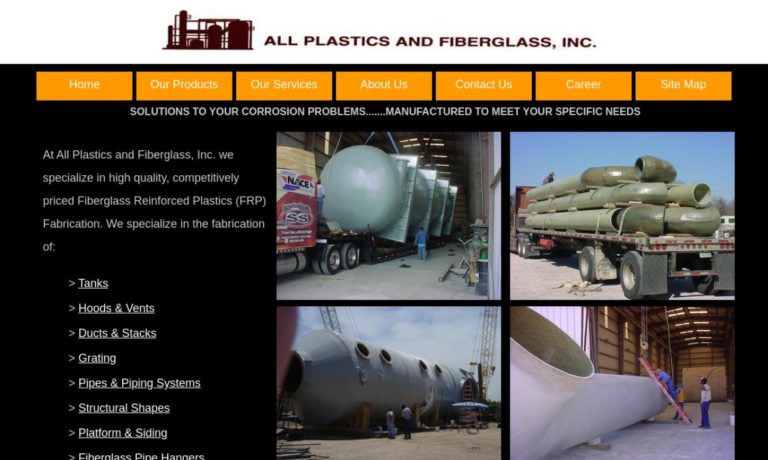

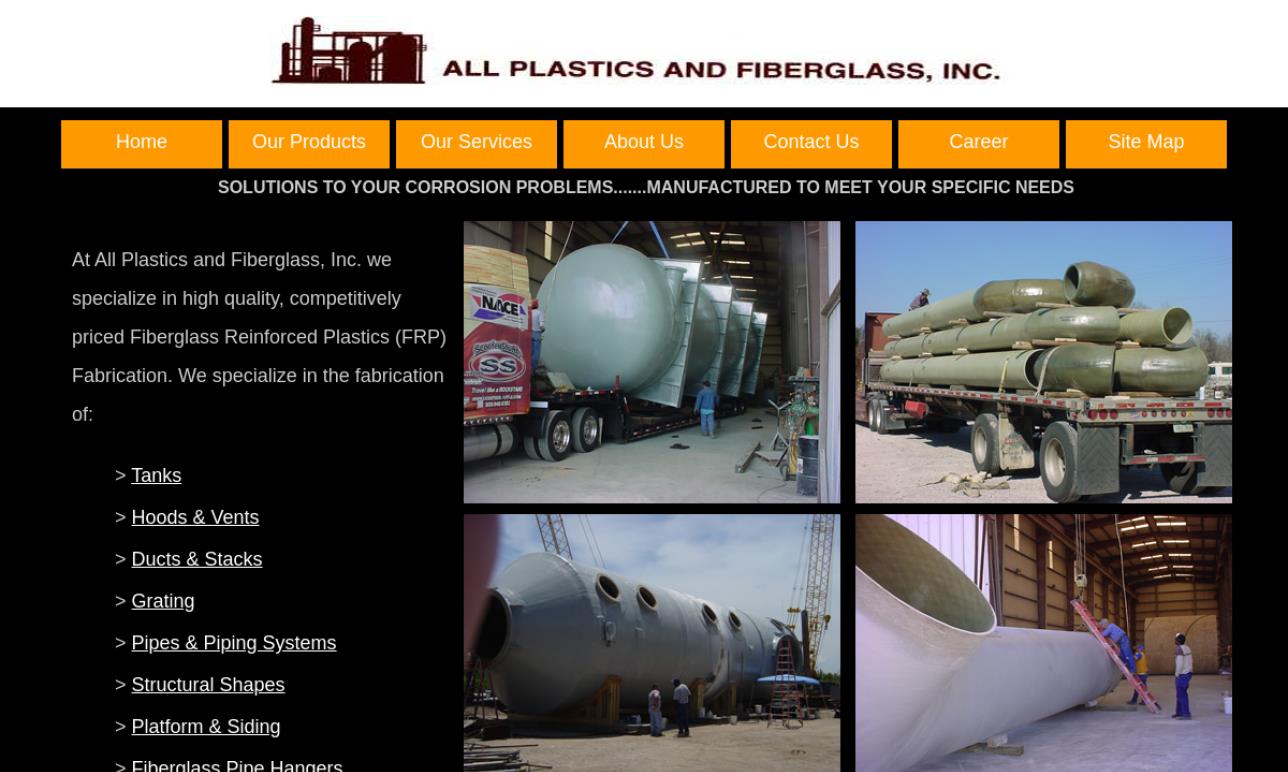

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Sterling Plastics, Inc., we are dedicated to providing comprehensive solutions in plastic materials, serving the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of...

At CYLEX Plastics, we pride ourselves on being a leading provider of comprehensive solutions in plastic materials, catering to the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a...

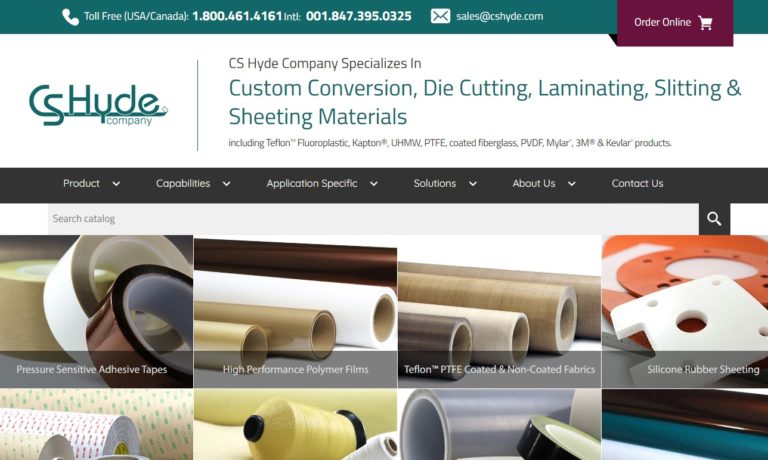

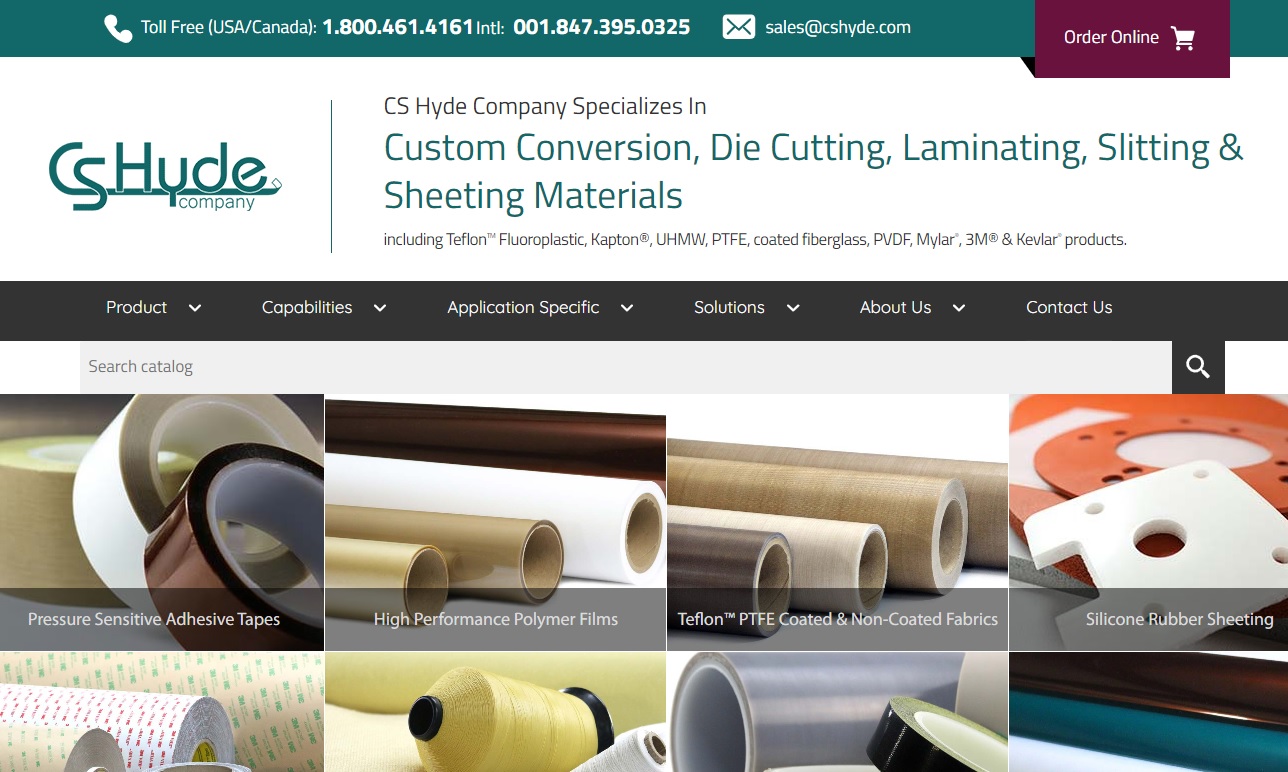

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Since 1967, Adams Plastics has specialized in plastics and PVC materials. As worldwide suppliers of plastics we can help you with your plastic sheeting, slitting, recycling, die cutting and more. Our product line includes clear plastic, coated vinyls, polypropylene and tinted clear plastics.

More Plastic Sheet Manufacturers

Consumer products, packaging, plastic containers and many other industries use plastic sheets in thermoforming processes such as vacuum forming, pressure forming and inline thermoforming. The automotive, aerospace, petrochemical, food and marine industries use raw, thick gauged plastic sheets and blocks to machine industry-specific parts.

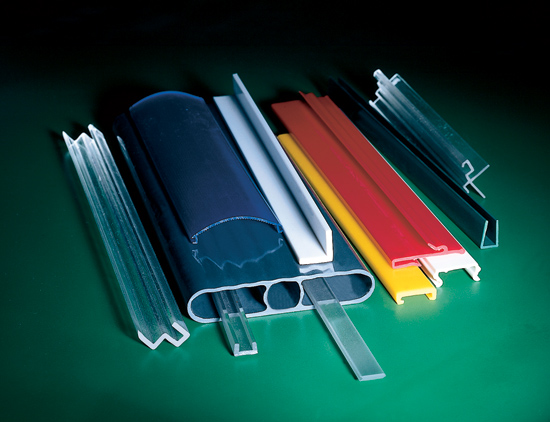

Plastic sheets are used as signage, and clear acrylic and Plexiglas sheets make excellent windows, large picture frames, barriers and point of purchase displays. Plastic sheeting is extruded the same way plastic channels and profiles are, with an additional end process. Plastic sheet manufacturers feed plastic pellets or flakes into a hopper that then feeds the raw plastic into a screw conveyor.

The screw conveyor shears and pushes the material along, heating and "plasticizing" the pellets into molten plastic. As the conveyor continues to turn, molten plastic is pushed out through a flat die. Instead of being instantly cooled, the flat shape is pulled and stretched by grips into wider sheets, which are then fed into a series of round metal cooling "calenders" and are ultimately wound onto spools.

Thicker gauge sheets are cut and stacked flat, ready to be thermoformed into many different shapes. Dies can also be round, so that as the plastic is extruded through the conveyor its tube shape is sheared in half, and both top and bottom are stretched into flat sheets separately. Sometimes additives and coating resins are added to the surface of the plastic sheet during the calendering process.

Plastic sheets may be fabricated from a number of different plastic materials, including HDPE, LDPE, PETG, PVC, polypropylene, polystyrene, vinyl and acrylic; different applications call for different properties of strength, flexibility, hardness, corrosion resistance and color, which is why so many styles of plastic have been created.

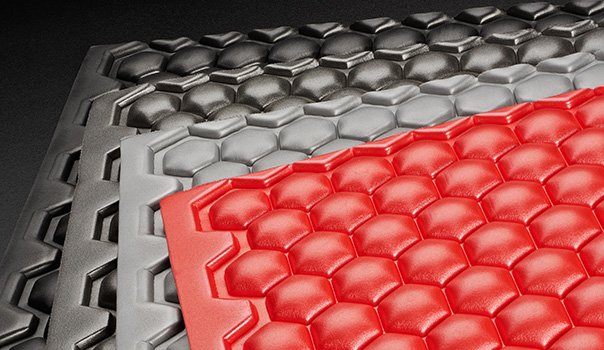

Some industries use plastic sheets with minor alterations for applications such as cutting boards, business signs, Plexiglas windows and silk-screening. Vacuum and pressure forming plastics manufacturers, however, choose plastic sheets with fine to medium gauges to be further processed into three dimensional products.

Vacuum formed products are made by heating a plastic sheet until it is flexible, then introducing a male mold underneath the plastic sheet and vacuuming the heated plastic sheet to the mold so it takes the mold's exact shape. The pressure forming process is identical, except that a female mold is introduced and the heated plastic sheet is vacuumed into it.

Blister packs and many packaging items are fabricated this way, as well as disposable utensils, containers, bathtubs and showers, marine seats and parts and all other hollow, shaped plastic parts made for industrial, commercial and residential use.

Die Cutting

Die Cutting Foam Fabricating

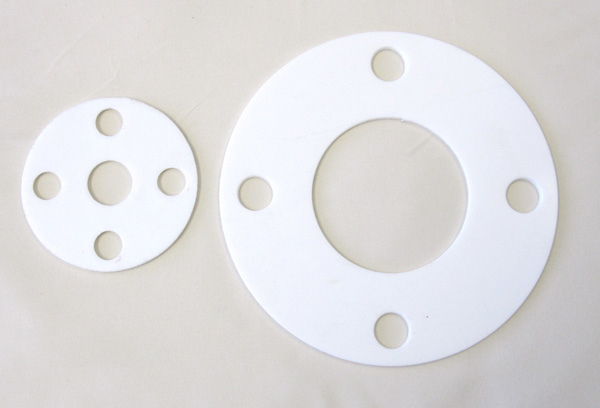

Foam Fabricating Gaskets

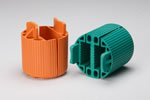

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

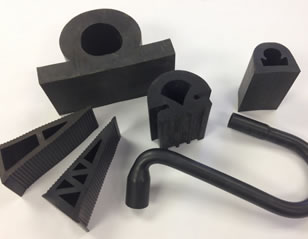

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services