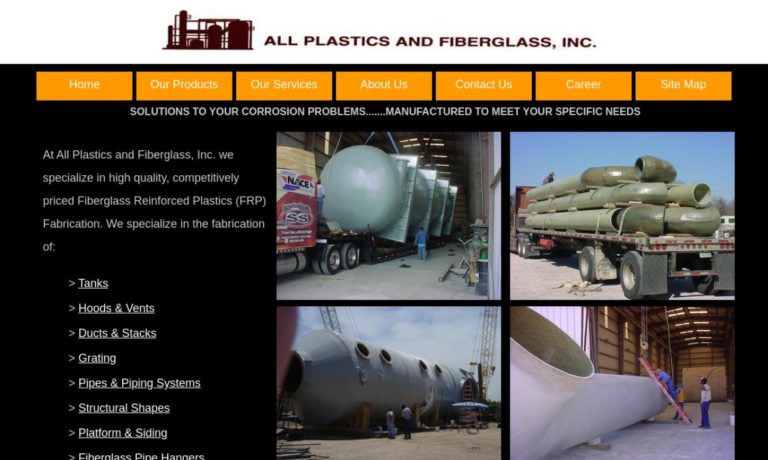

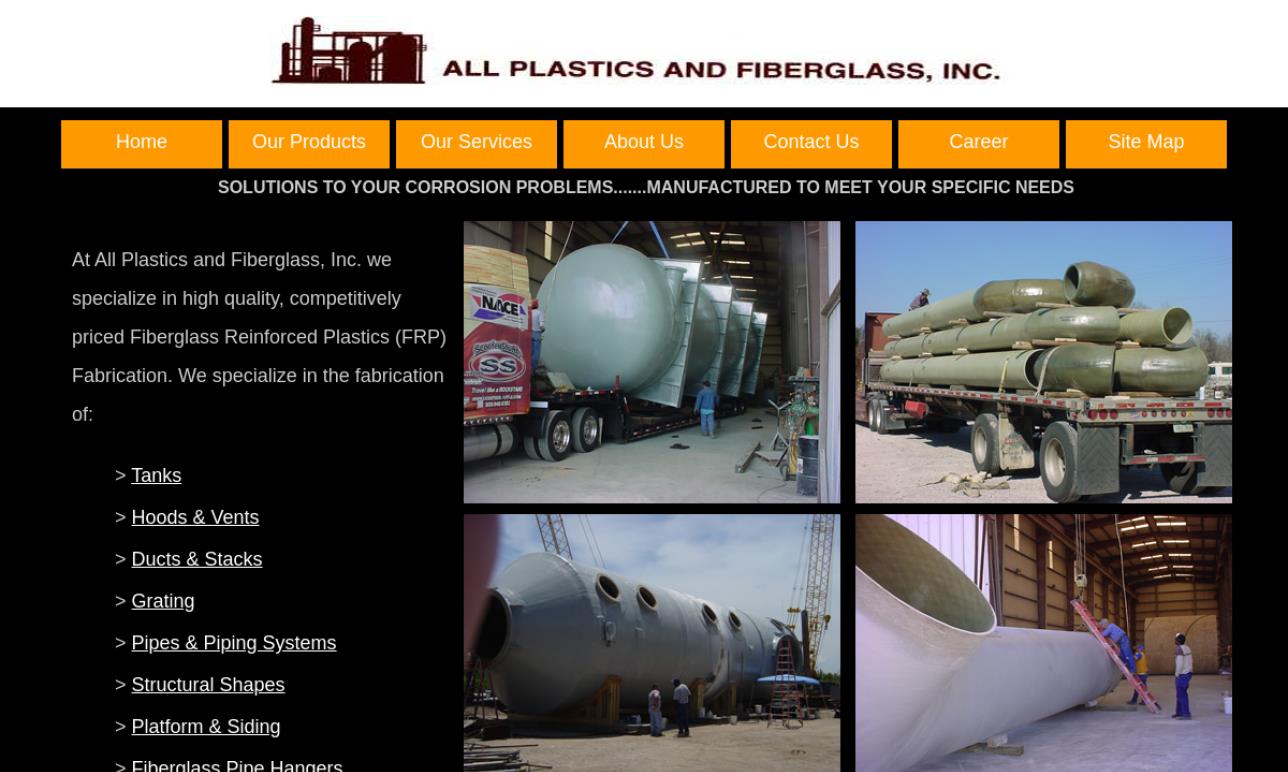

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Sterling Plastics, Inc., we are dedicated to providing comprehensive solutions in plastic materials, serving the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of...

At CYLEX Plastics, we pride ourselves on being a leading provider of comprehensive solutions in plastic materials, catering to the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a...

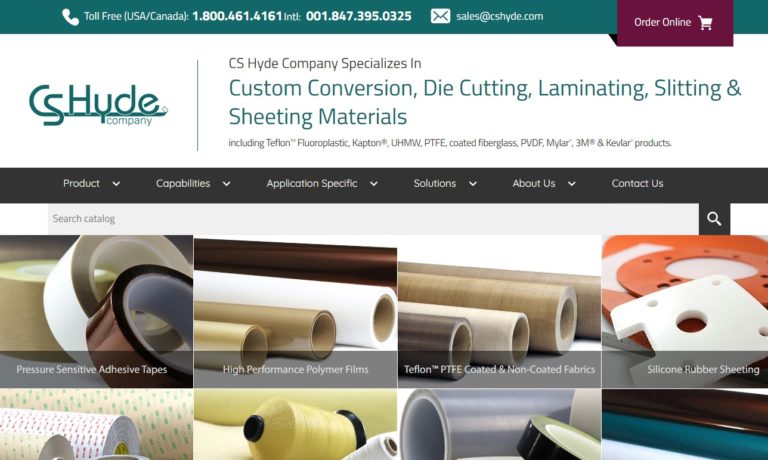

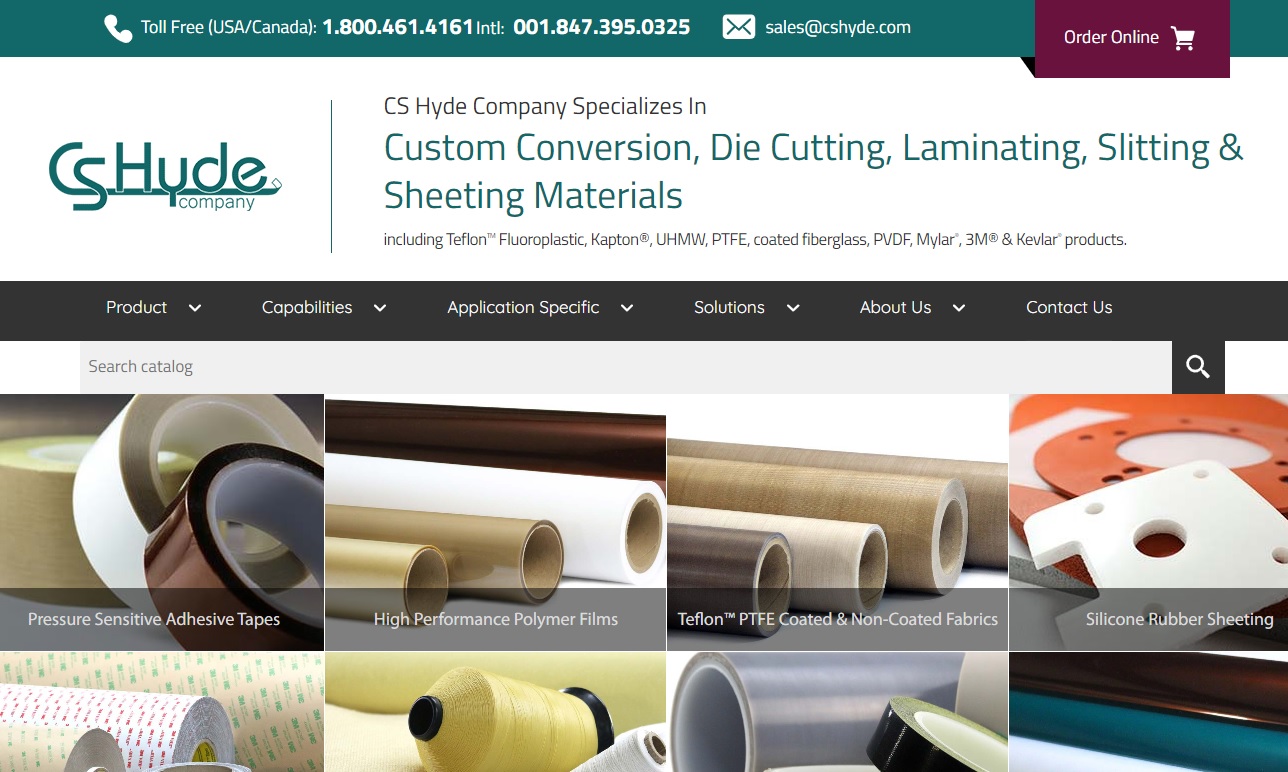

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Since 1967, Adams Plastics has specialized in plastics and PVC materials. As worldwide suppliers of plastics we can help you with your plastic sheeting, slitting, recycling, die cutting and more. Our product line includes clear plastic, coated vinyls, polypropylene and tinted clear plastics.

More Polystyrene Manufacturers

Abbreviated PS, this particular plastic is ubiquitous in daily life, second in use only to polyethylene. Polystyrene exhibits the same strength as unalloyed aluminum, but is much lighter and offers significantly increased flexibility.

Desirable properties such as good thermal and electrical insulation, resistance to acids, alkalis, oils and alcohols in addition to being lightweight and flexible make polystyrene products a popular and economic choice for a broad array of industries. Packaging, building, construction and architectural design make frequent use of this material.

Furthermore, polystyrene is chemically non-reactive, making its use popular in food, medical, biomedical and pharmaceutical industries as well as applications involving the storage of volatile chemicals. Products produced for such uses are often sterilized by irradiation or an ethylene oxide treatment.

Electronic housings, compact discs, cutlery, beakers, insulating panels, food trays, packaging products and window panels are just a few of the myriad polystyrene products available to accommodate the broad spectrum of industrial, commercial and residential use. A thermoplastic, PS is pliable when heated and rigid when cold allowing it to be easily recycled and remolded numerous times. As it is non-biodegradable, diligent recycling is essential to diminishing the environmental impact of this plastic material.

The many uses of polystyrene all begin with the same process of joining monomers to create the plastic polymers. Classified as a liquid hydrocarbon, PS is composed of the elements hydrogen and carbon. Through the free-radical polymerization of petroleum or the derivative phenylethene (another name for styrene), and using benzoyl peroxide as the initiator, these hydrocarbon monomers form covalent bonds with phenol groups to create polystyrene. Beyond this point polystyrene can be manufactured in a number of different ways.

The most recognizable pre-form of polystyrene is the trade marked extruded foam, Styrofoam. Also available in expanded foam, moldable solids or viscous fluids, polystyrene is supplied to hundreds of different industries in the most applicable pre-form. Injection molding, casting, extrusion and stamping are used to manufacture products from this dimensionally stable material.

Polystyrene manufacturers fabricate a diverse range of stock forms which may include plastic rods, plastic sheets, plastic films, pipes, tubes, plates and more. These may be utilized as finished products or can be processed further to satisfy particular specifications. In solid form, polystyrene is a colorless, glass-like rigid material.

Polystyrene softens just above 100 degrees Celsius and becomes viscous at 185 degrees Celsius. Different fillers can be added to molten polystyrene during processing to alter porosity, strength, flexibility and thermal capabilities.

Die Cutting

Die Cutting Foam Fabricating

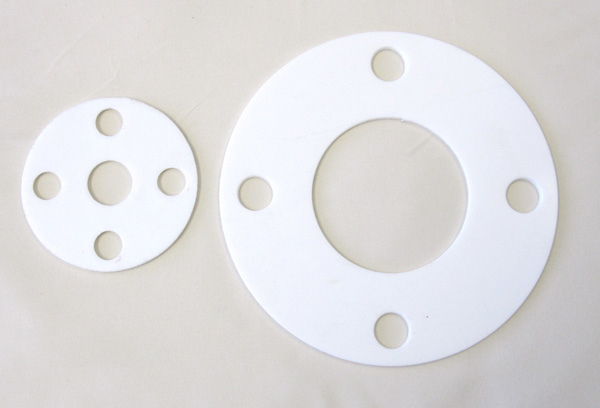

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

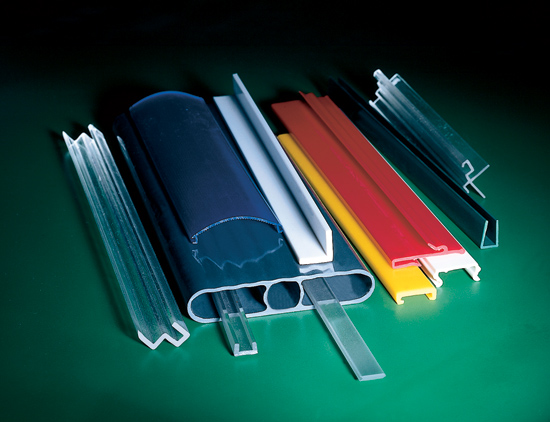

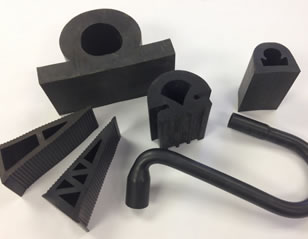

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

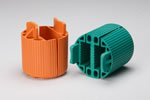

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services