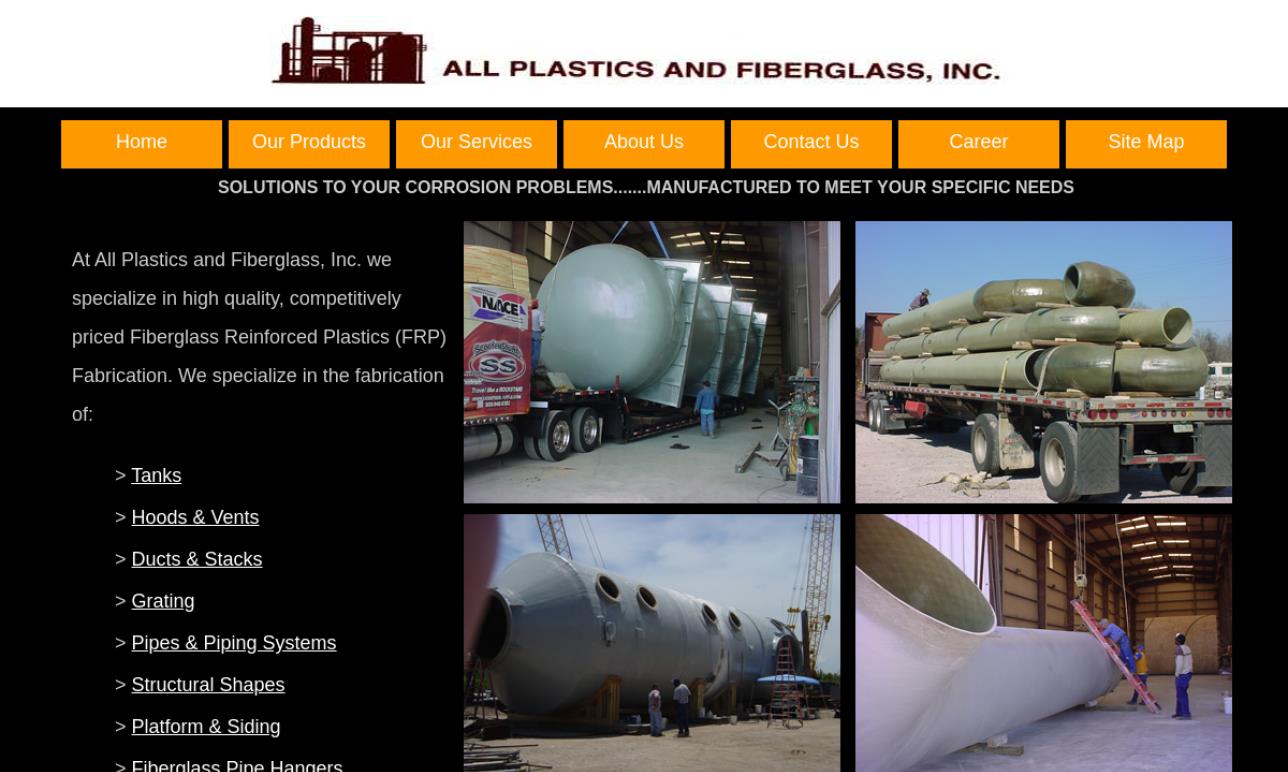

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Sterling Plastics, Inc., we are dedicated to providing comprehensive solutions in plastic materials, serving the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of...

At CYLEX Plastics, we pride ourselves on being a leading provider of comprehensive solutions in plastic materials, catering to the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a...

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Since 1967, Adams Plastics has specialized in plastics and PVC materials. As worldwide suppliers of plastics we can help you with your plastic sheeting, slitting, recycling, die cutting and more. Our product line includes clear plastic, coated vinyls, polypropylene and tinted clear plastics.

More Thermoplastic Manufacturers

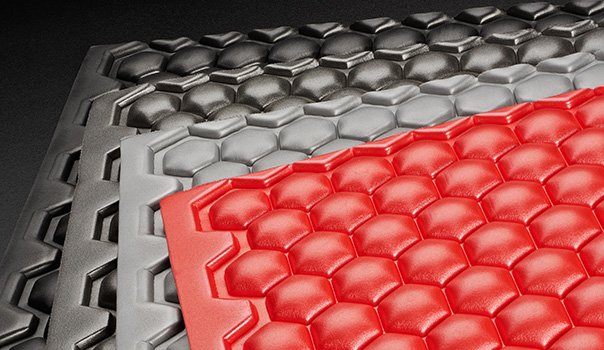

Thermoplastics are any plastic polymer substance that becomes malleable or moldable at a specific elevated temperature and solidifies upon cooling. Thermoplastics encompass all plastic materials that soften and may return to a liquid state when heated but solidify and become rigid when cooled.

Thermoplastic Polymers Properties

Typically, polymers are chosen to replace metal in structural applications. However, a like-for-like substitution of a polymer component for a metallic section will often reduce weight.

Polymers can be easily molded into shapes where metals are challenging. The engineer can create a desirable shape that facilitates plastic forming, reduce cost and weight, and improve aesthetics by employing a polymer. Since the polymer portion does not need painting for corrosion protection, like the similar metal part, further cost savings is realized. The choice of a particular polymer will depend on the end-use environment's temperature, chemical composition, and mechanical needs.

Polymerization Process

The process of polymerization is used to connect monomers, or tiny molecules, to create long chains to create thermoplastics. Many thousands of monomers can be used to create a single polymer chain. While there are weak forces between chains, strong covalent bonds connect the atoms in polymer chains.

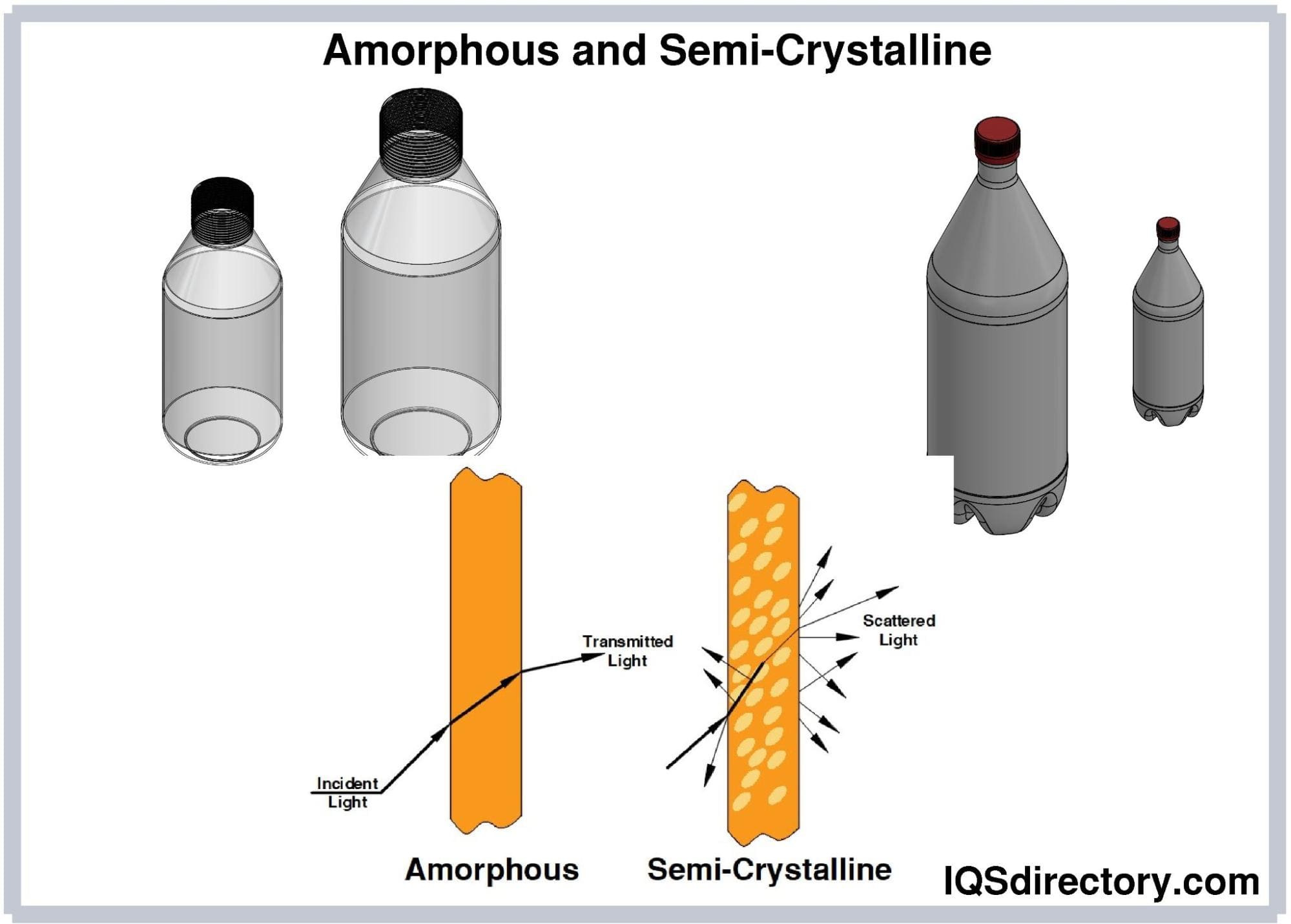

Side branches may be present in polymer chains depending on the kind of monomer. A polymer chain can form organized; crystalline areas known as spherulites only contain a few short side branches. On the other hand, the polymer is amorphous if the chain has numerous big side branches since this prevents the formation of organized regions.

Amorphous polymers include acrylonitrile-butadiene-styrene (ABS), polyvinyl chloride (PVC), and polystyrene (PS) (ABS). Since crystallites deflect light, amorphous polymers are employed in applications where optical clarity is essential. However, these amorphous polymers lack a crystalline structure and are less resilient to chemical assault and environmental stress cracking.

Before a thermoplastic polymer can be utilized, it is typically combined with additives to enhance its functionality, stability, or appearance. Additives may include stabilizers, plasticizers, lubricants, flame retardants, and colorants. Stabilizers are added, for instance, to lessen deterioration brought on by heat or sunlight. At the same time, plasticizers are used to make amorphous chain segments more mobile, lowering the glass transition temperature and reducing brittleness.

Types of Thermoplastics

The majority of thermoplastics are made from polymeric resins. These are extended chains of several smaller monomers joined by covalent bonds. Condensation polymers and addition polymers are the two primary categories of thermoplastics. Plastics that create covalent connections without losing atoms or molecules are classified as extra polymers. On the other hand, during bonding, condensation polymers consistently lose a molecule, typically water.

Based on their chemical makeup and how they form bonds, the materials within these classifications can be divided into monomers, intermediates, binders, base polymers, elastomers, and rubber materials. The unique characteristics of thermoplastics might further categorize them. To improve or change the properties of plastic material, thermoplastic makers can add additives like powders, fibers, plasticizers, and ceramics in addition to the polymerized ingredients. These are crucial in the manufacture and processing of thermoplastics.

Considerations When Purchasing Thermoplastics

Thermoplastics come in a wide range of densities and crystalline structures, and they all have unique features. Therefore, understanding a plastic's specifications concerning the finished product or application is crucial. The correct thermoplastic for a given application depends on various criteria, including additives, manufacturing, and raw material availability. Physical, mechanical, electrical, and optical characteristics, as well as melting point, size, and flexibility, are additional factors.

When considering any thermoplastic, one must specifically consider the following factors.

- The resin viscosity needs to be low enough to penetrate the reinforcement.

- The size of the molding: Because cure reactions are sometimes exothermic, thick moldings may require a slower rate of curvature to prevent an uncontrolled temperature rise during the curing process, which could be enough to harm the molding.

- The speed of reaction plays a significant role in the volume of articles produced.

- The resin needs to moisten and stick to the reinforcement to be compatible.

- Moisture content: Some polymers do not perform as well as others in wet conditions. Ingress of moisture into a laminate might result in a serious loss of characteristics.

Choosing the Right Thermoplastics Supplier

To make sure you have the most beneficial outcome when purchasing thermoplastics from a thermoplastic supplier, it is important to compare at least 5 companies using our list of thermoplastic suppliers. Each thermoplastic supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each thermoplastic company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple thermoplastic companies with the same form.

Die Cutting

Die Cutting Foam Fabricating

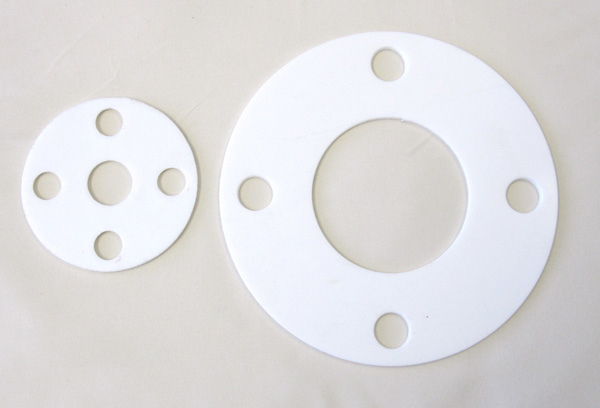

Foam Fabricating Gaskets

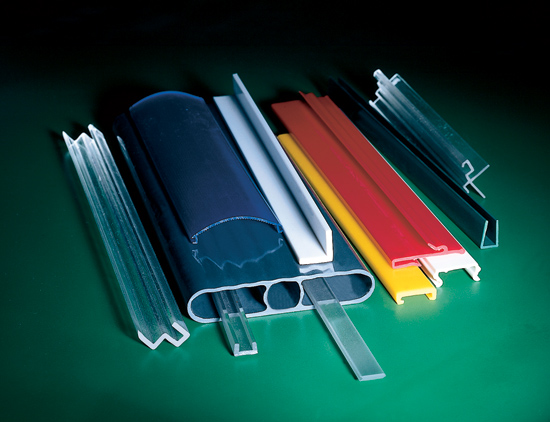

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

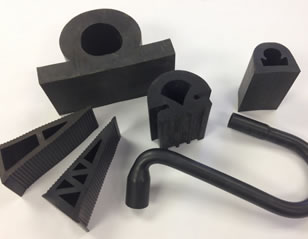

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services