Porex Filtration Group

Porex Filtration GroupRequest A Quote

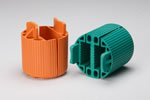

Fairburn, GAPorex Filtration Group is a global manufacturer and distributor of porous plastics and other advanced porous materials. The company has a long history of innovation and specializes in designing and producing custom-engineered products that meet the unique needs of its customers across a wide range of industries. Porex's expertise in porous plastics allows it to create products with controlled pore size, pore volume, and other key characteristics, which can be tailored to suit specific applications. The company's porous plastics can be found in a variety of products, from medical devices to consumer goods to industrial equipment. One of Porex's key strengths is its ability to work closely with its customers to develop custom solutions. The company has a team of experienced engineers and materials scientists who can provide design and prototyping services, as well as help with material selection and product development. This allows Porex to offer a high level of customization, ensuring that its products meet the precise needs of its customers. Porex also offers a range of other services, including precision cutting, drilling, and other machining services. The company's state-of-the-art facilities enable it to produce parts with tight tolerances and high precision, ensuring that its products are of the highest quality. In addition to its plastics products and services, Porex is also committed to sustainability. The company has implemented a number of initiatives to reduce its environmental impact, including reducing waste and energy usage in its manufacturing processes. Porex also uses sustainable materials and works with suppliers who share its commitment to sustainability. Overall, Porex is a leading provider of porous plastics and other advanced porous materials, offering a range of products and services tailored to the unique needs of its customers. With a focus on innovation, customization, and sustainability, Porex is well-positioned to meet the evolving needs of its customers across a wide range of industries.

Die Cutting

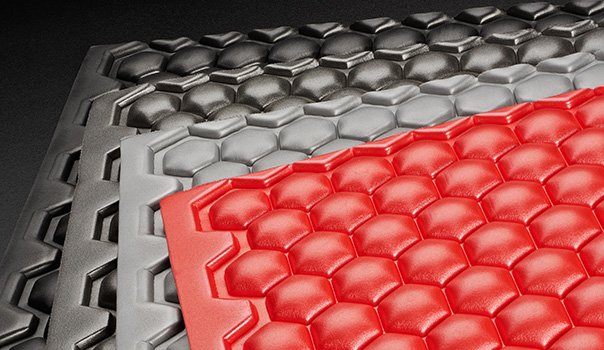

Die Cutting Foam Fabricating

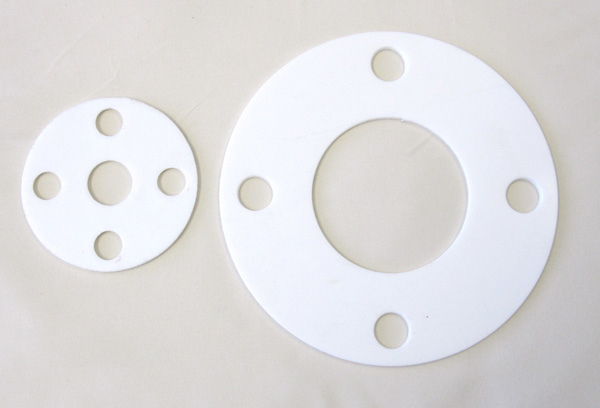

Foam Fabricating Gaskets

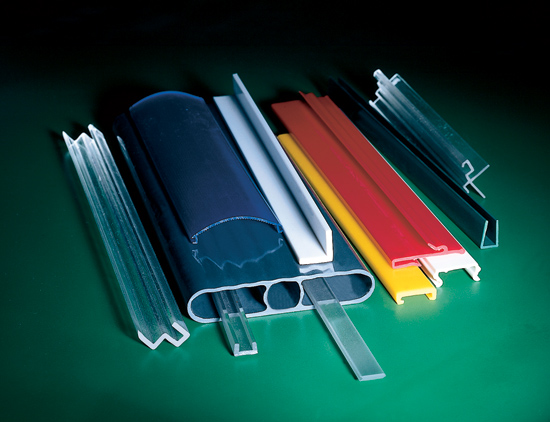

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

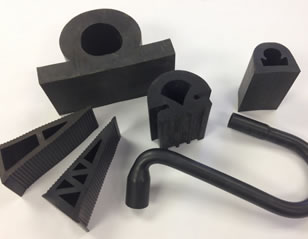

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services