All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Sterling Plastics, Inc., we are dedicated to providing comprehensive solutions in plastic materials, serving the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of...

At CYLEX Plastics, we pride ourselves on being a leading provider of comprehensive solutions in plastic materials, catering to the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a...

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Since 1967, Adams Plastics has specialized in plastics and PVC materials. As worldwide suppliers of plastics we can help you with your plastic sheeting, slitting, recycling, die cutting and more. Our product line includes clear plastic, coated vinyls, polypropylene and tinted clear plastics.

More Delrin Manufacturers

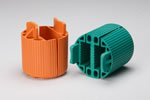

The word Delrin is a trademark for a particular type of acetal polyoxymethylene. This thermoplastic can be used in place of metal in commercial, industrial, and residential applications. POM is the abbreviation for this homopolymer and copolymer plastic product. These engineering thermoplastics have high strength and outstanding dimensional stability.

Design of Delrin Manufacturing

Anhydrous formaldehyde reacts with alcohol to create semiformal, the precursor of homopolymers. This material is dehydrated before being polymerized by ionic catalysis. Polyoxymethylene is then stabilized through a reaction with acetic anhydride. Formaldehyde is also used in copolymers, although it is handled differently. Formaldehyde is changed by acid catalysis into trioxane, which is then dried and distilled to produce Delrin copolymers.

Both kinds of plastic are frequently offered as hot, granular forms that have been melted. The material can then be shaped into the required shape using injection molding or extrusion techniques used by Delrin producers. When choosing a mold, remember that polyoxymethylene can shrink by as much as 2% during fabrication.

For distribution, manufacturers use rotational molding and blow molding when making stock shapes, such as plastic rods, films, and sheets. Delrin manufacturers frequently use auxiliary operations like turning, milling, drilling, and precision machining to generate application-specific parts, even if rods and sheets may be the end output. Delrin is a thermoplastic. Therefore, it may be melted, remolded, or extruded as necessary.

Assembling Delrin Components

When selecting a production material, keep the component assembly in mind. There are numerous ways to assemble Delrin components. Delrin components can be assembled and disassembled using self-tapping screws, snap-fits, and press-fits, while permanent assembly procedures include welding, adhesives, and riveting. Adhesives can be used for prototypes or limited production runs of a large, complex assembly, but they lack the strength required for end-use performance. If performance is crucial, employing glued joints is advised. Manufacturers use sandpaper or chemicals to clean and degrease surfaces for better assembly results.

Benefits of Using Delrin

- Delrin provides a harmony between the remarkable qualities of metals and polymers. As a result, Delrin is the perfect material for high-impact and large load-carrying applications.

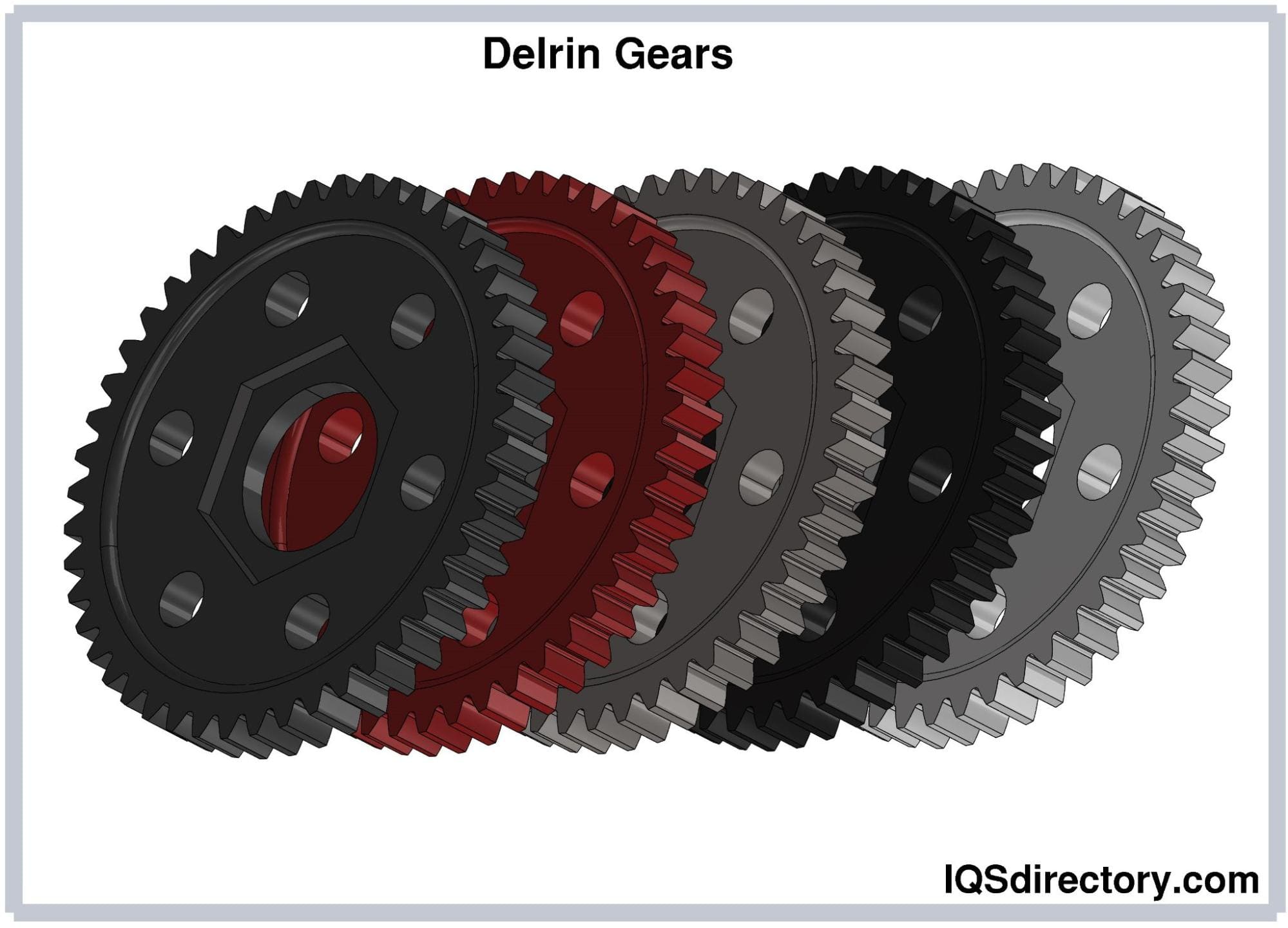

- Delrin has superior dimensional stability. It can maintain its original shape and dimensions when exposed to temperature and humidity changes, making it especially helpful in applications that depend on dimensional changes, including gears and bearings.

- Due to Delrin's resistance to moisture, it can perform in situations with high moisture and humidity levels while maintaining its mechanical and physical qualities. A few examples of parts that can be improved using Delrin are pumps, valves, and plumbing fixtures.

- Delrin is exceptionally durable under high stress because it has tremendous impact and creep resistance.

- Delrin is chemically resistant to fuels and solvents and is particularly suitable for piping, tank, and vessel fittings in the petrochemical industry because it is chemically resistant to fuels and solvents. In addition, Delrin functions well in petroleum-based applications.

- Delrin is an easy product to fabricate. Despite its great strength, it may be easily cut into any required shape using various tools.

- Delrin has outstanding wear and abrasion resistance. The material is also well known for its resistance to wear and abrasion. This property is particularly important in gears or applications with regular friction. For example, Delrin fittings can be used in abrasive material-conveying piping systems.

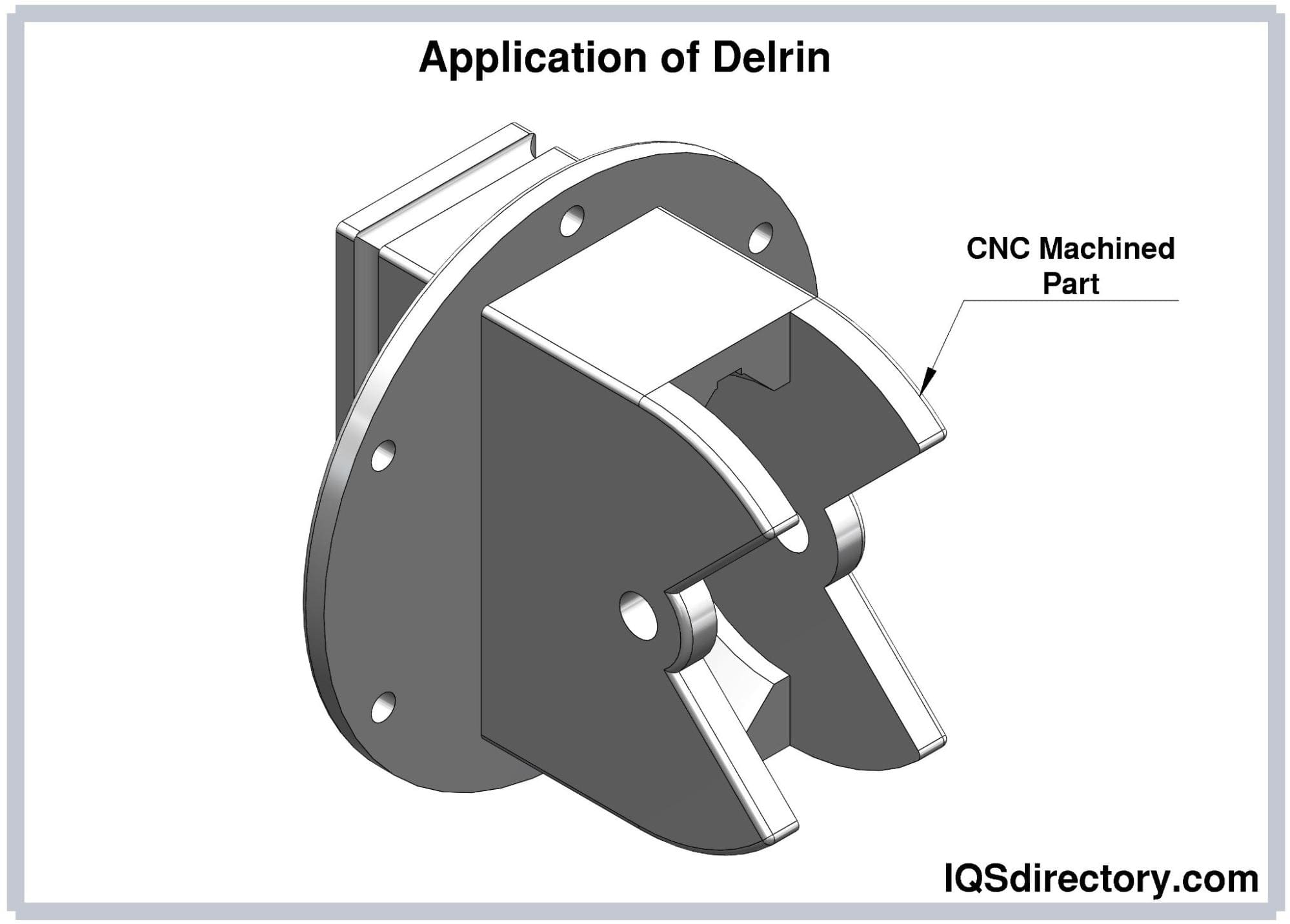

Application Of Delrin

Many machinists favor Delrin because it is simple to machine with 3- and 5-axis tools. Additionally, it can be 3D printed and injection molded, making it a flexible material with many uses. Any industry that requires high-performance engineering components, including the automotive and consumer electronics industries, uses Delrin components.

High-performance components like gear wheels, housings, screws, nuts, and pump components are often made of Delrin. Delrin can also make electrical engineering components like connectors, electronic parts, coverings, and insulators. Door locks and articulated shells are only two examples of car parts made from Delrin. Delrin is also used in various medical devices and goods, including insulin pens and metered-dose inhalers.

Delrin is frequently used to replace metal components. Due to its composition and qualities, Manufacturers can use Delrin to satisfy various customized client requirements because it is offered in a range of special grades.

Manufacturers of Delrin can provide upgrades to boost its functionality. Modifications may include thermal and oxidative stabilizers, lubricants, and fillers. These modifications improve Delrin’s inherent properties and make it resistant to moisture, chemical corrosion, solvents, fuels, and creep. Stock forms are widely accessible and can be used directly as the finished product or processed further to produce safe locks, gears, bindings, bearings, fan blades, nuts, screws, wheels, kettles, and other items. However, manufacturers shouldn’t use Delrin in very acidic environments because it will quickly deteriorate.

Choosing the Proper Delrin Manufacturer

To make sure you have the most positive outcome when purchasing Delrin from a Delrin manufacturer, it is important to compare at least 4 manufacturers using our Delrin directory. Each Delrin manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Delrin business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Delrin businesses with the same quote.

Die Cutting

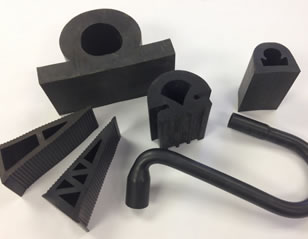

Die Cutting Foam Fabricating

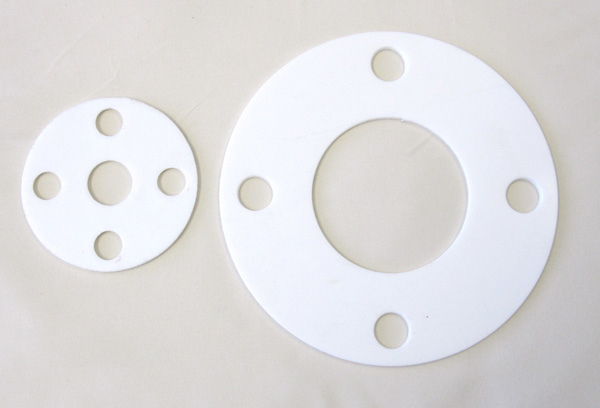

Foam Fabricating Gaskets

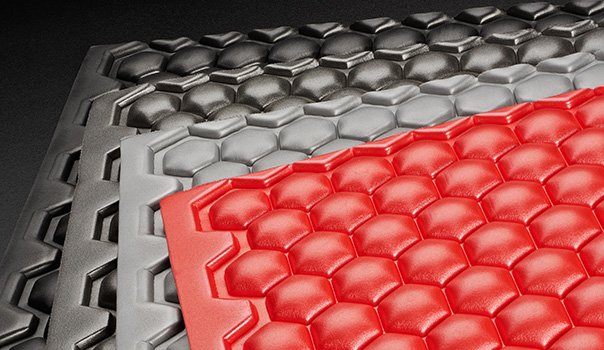

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

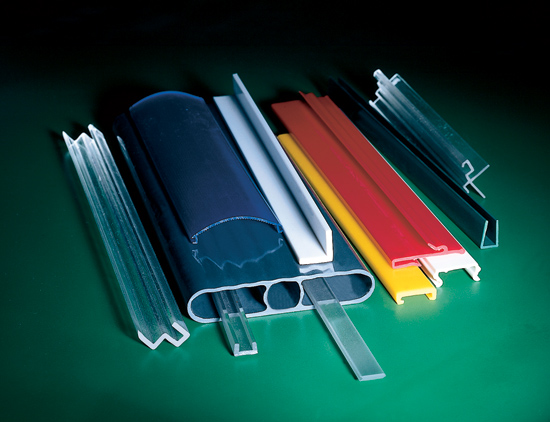

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services