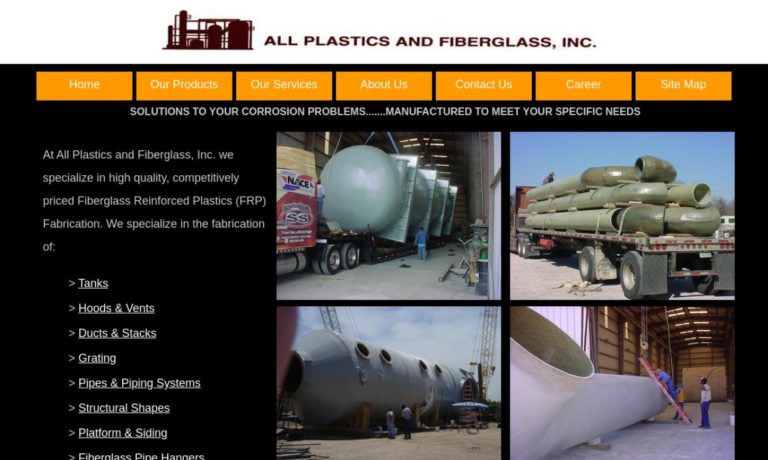

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Sterling Plastics, Inc., we are dedicated to providing comprehensive solutions in plastic materials, serving the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a wide range of...

At CYLEX Plastics, we pride ourselves on being a leading provider of comprehensive solutions in plastic materials, catering to the diverse needs of our valued clientele. With years of experience and expertise in the plastics industry, we have established ourselves as a trusted partner known for our commitment to quality, innovation, and customer satisfaction. Our product portfolio encompasses a...

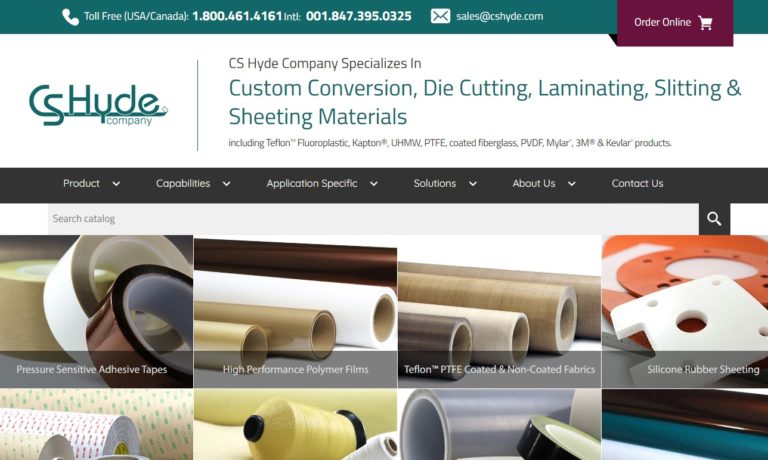

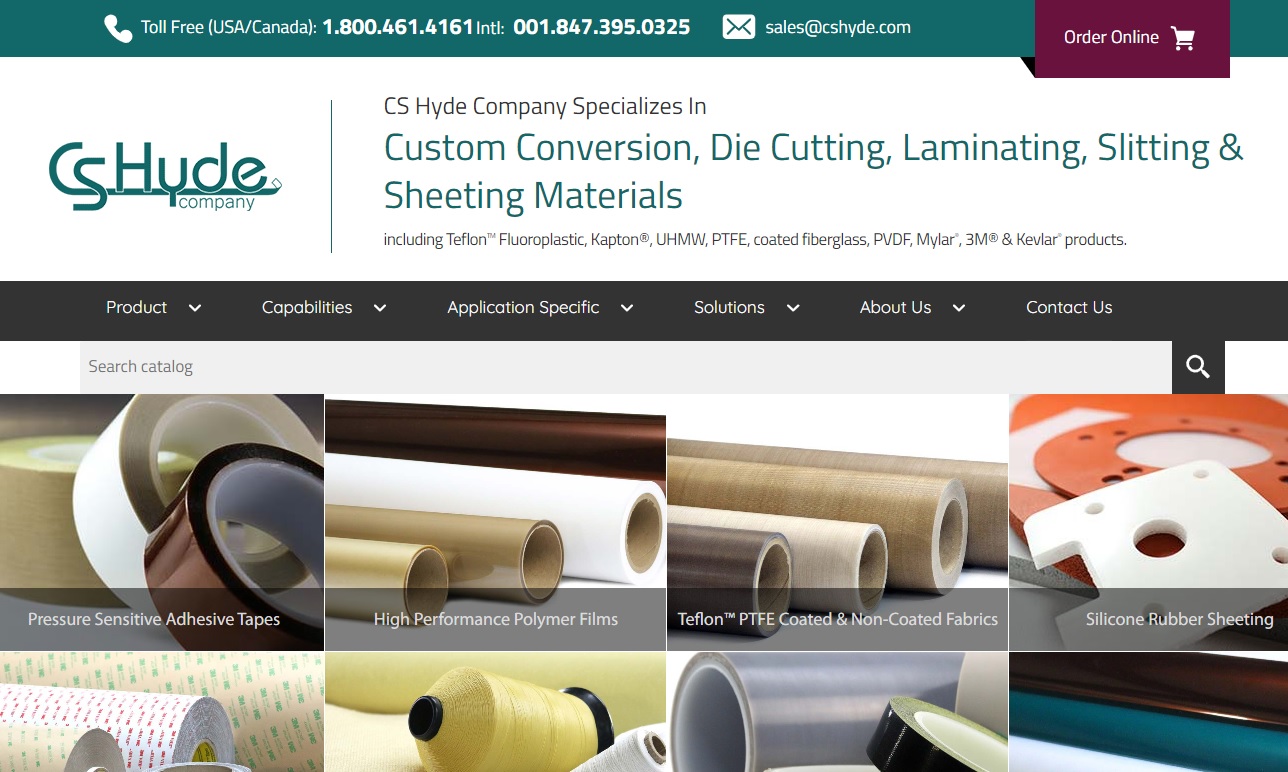

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Since 1967, Adams Plastics has specialized in plastics and PVC materials. As worldwide suppliers of plastics we can help you with your plastic sheeting, slitting, recycling, die cutting and more. Our product line includes clear plastic, coated vinyls, polypropylene and tinted clear plastics.

More Polypropylene Manufacturers

Polypropylene (PP) is less dense than water and has a melting point of 320°F.

Die Cutting

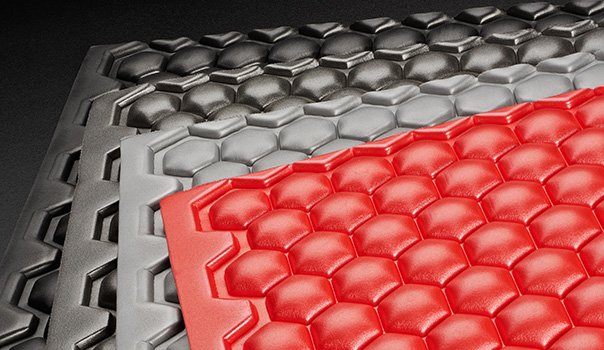

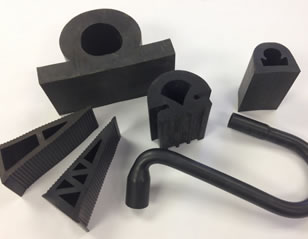

Die Cutting Foam Fabricating

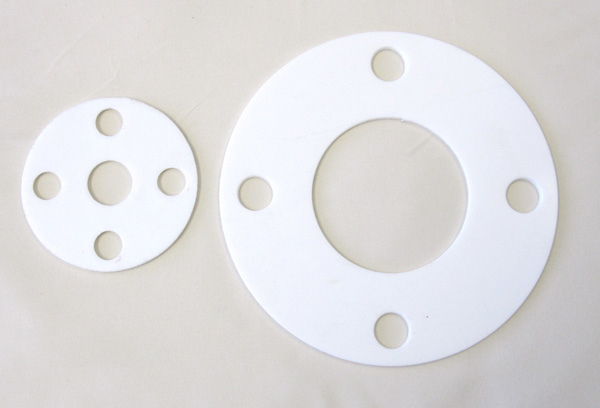

Foam Fabricating Gaskets

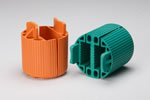

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

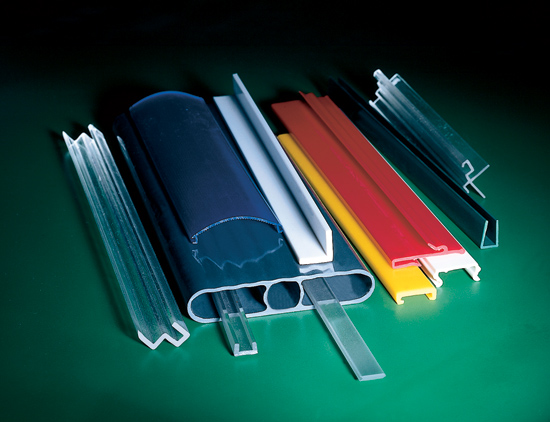

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services