At Porex Filtration Group, we are a global leader in porous plastics technology, dedicated to providing innovative solutions that enhance product performance and improve the lives of people around the world. With decades of experience and a relentless commitment to excellence, we have established ourselves as trusted partners in the plastics industry, offering a comprehensive range of products...

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Plastic-Craft® Products, our business is plastics. We have an extensive inventory of plastic materials to suit your needs, and also maintain a complete machine shop to fabricate plastic parts to your specifications. Let us meet your plastics requirements. We have over 50 years of service behind us. We are always available to discuss the application of our service to your unique operation.

Atlas Fibre is a supplier of stock thermoset shapes in sheet, rod and tube in the following grades: G3, G5, G7, G9, G10, G11, FR4 and canvas, linen and paper phenolic. All materials are Mil-Spec and NEMA certified. We also have extensive CNC milling and turning capabilities; CNC sawing, sanding, and material fabrication for all thermoset materials. We can also machine and fabricate all types of...

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Boedeker Plastics stocks the widest variety of engineering and industrial plastics in the industry. The people of Boedeker have the unique knowledge necessary to take customer service a step beyond others in the field providing in-house engineering assistance. Whether you need ten miles or ten inches, Boedeker Plastics has all of your plastic materials, sheets, rods, tubes and custom components.

Send Requests For Quote to Multiple Polycarbonate Manufacturers Suppliers Near You

Provide your project details, and we'll connect you to 5-20 qualified Polycarbonate Manufacturers companies in your region. 100% free.

Get InformationManually Sourcing U.S./Canadian Manufacturers for 20+ Years

More Polycarbonate Manufacturers

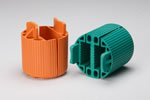

Characteristics of polycarbonate include good light transmission, the ability to be machined or thermoformed and good dimensional stability.

Polycarbonate is FDA approved. It is perfect for applications requiring a lightweight, transparent material that is virtually indestructible. Acrylic is known for being a much stronger alternative to glass, but its strength is nothing compared to the bullet-proof hardness of polycarbonate. Also, polycarbonate is one-third the weight of the lightweight acrylic as well.

Both are thermoplastic polymers, which means that they both melt when heated to a certain degree and harden when they cool, a process that can be repeated numerous times. This means that polycarbonate and acrylic plastics are able to be reshaped and recycled, making them more environmentally friendly then thermoset plastics.

Other thermoplastic polymers include; Delrin, which is the trademark name of acetal polyoxymethylene, is a plastic known for its durability and versatility; polystyrene is just as popular in its preformed form of Styrofoam as it is in its final form; PVC, or polyvinyl chloride, has the ability to retain vivid colors, which makes it a popular plastic for home decorating objects such as shower curtains, furniture and interior paneling.

Polycarbonate is a plastic material that can be found in most homes today in the form of CD and DVD discs. Polycarbonate manufacturers also create many other polycarbonate products which are used in applications like shatter-resistant display cases, security barriers, aircraft panels, machine guards, electronic housings and burglar-resistant glazing. One of the major industries that utilize polycarbonate today is the vision care industry.

Because it is transparent and incredibly strong as well as having a high refractive index, polycarbonate is currently the most popular substance for corrective lenses. The high refractive index of a plastic refers to its ability to bend light that goes through it, which is in essence how vision is corrected with prescription lenses. Also, because polycarbonate is naturally highly refractive, corrective lenses made from them are able to be significantly thinner then lenses made from other substances.

Sunglasses, with and without prescription lenses, are also often made with polycarbonate, since it is able to retain fillers that block ultra-violet rays well. Polycarbonate is available in scratch-resistant, flame retardant, anti-static and glass-filled forms. The only down-side to purchasing polycarbonate is that it is more expensive than acrylic or glass, although the fact that it lasts so much longer may outweigh that negative characteristic.

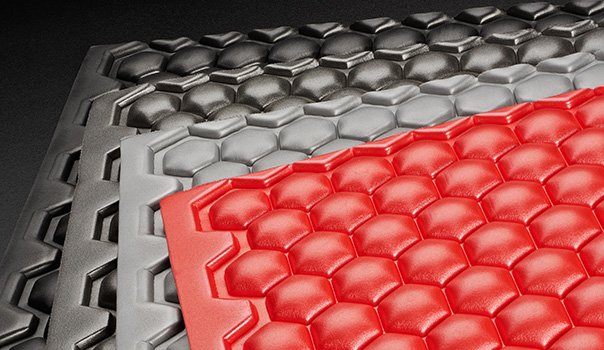

Die Cutting

Die Cutting Foam Fabricating

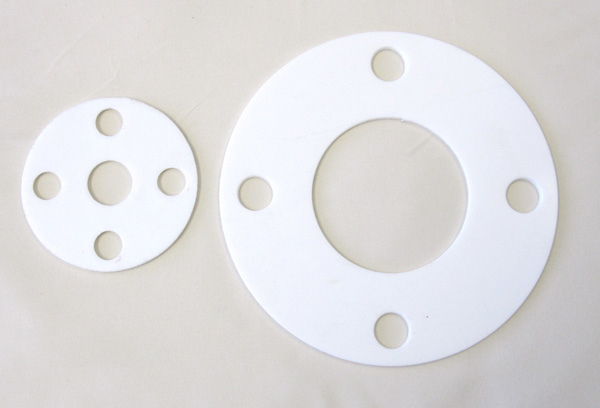

Foam Fabricating Gaskets

Gaskets Plastic Fabrication

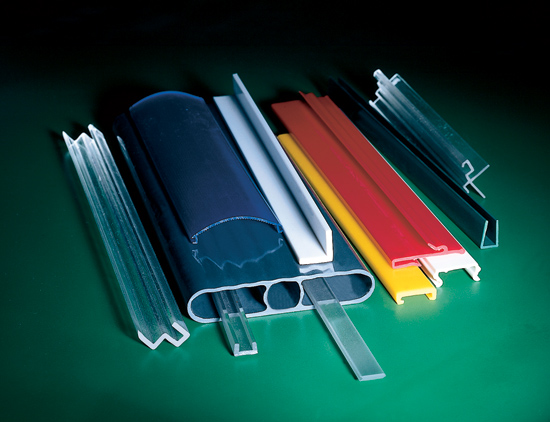

Plastic Fabrication Plastic Materials

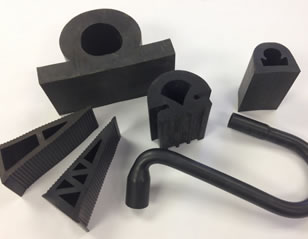

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services