At Porex Filtration Group, we are a global leader in porous plastics technology, dedicated to providing innovative solutions that enhance product performance and improve the lives of people around the world. With decades of experience and a relentless commitment to excellence, we have established ourselves as trusted partners in the plastics industry, offering a comprehensive range of products...

All Plastics and Fiberglass performs fabrication for fiberglass and plastics. Among the standard products we produce are ducts, grating, structural shapes, pipe hangers and tanks. We do custom fabrication on tanks and pipe hangers. We also make prefabricated piping systems, handrails and more. We have built a reputation on high quality and superior service for more than two decades.

At Plastic-Craft® Products, our business is plastics. We have an extensive inventory of plastic materials to suit your needs, and also maintain a complete machine shop to fabricate plastic parts to your specifications. Let us meet your plastics requirements. We have over 50 years of service behind us. We are always available to discuss the application of our service to your unique operation.

Atlas Fibre is a supplier of stock thermoset shapes in sheet, rod and tube in the following grades: G3, G5, G7, G9, G10, G11, FR4 and canvas, linen and paper phenolic. All materials are Mil-Spec and NEMA certified. We also have extensive CNC milling and turning capabilities; CNC sawing, sanding, and material fabrication for all thermoset materials. We can also machine and fabricate all types of...

CS Hyde has been providing high-end plastic materials since our founding in 1996, and has become a leading distributor and converter to a wide variety of markets. Materials we have available include Teflon Fluoroplastic, PTFE, Mylar®, Kevlar®, and more. We utilize the most high-tech converting equipment to provide superior products to our customers in a short time frame. It is our continuous...

Boedeker Plastics stocks the widest variety of engineering and industrial plastics in the industry. The people of Boedeker have the unique knowledge necessary to take customer service a step beyond others in the field providing in-house engineering assistance. Whether you need ten miles or ten inches, Boedeker Plastics has all of your plastic materials, sheets, rods, tubes and custom components.

Send Requests For Quote to Multiple Plastic Film Manufacturers Suppliers Near You

Provide your project details, and we'll connect you to 5-20 qualified Plastic Film Manufacturers companies in your region. 100% free.

Get InformationManually Sourcing U.S./Canadian Manufacturers for 20+ Years

More Plastic Film Manufacturers

These polymers are made up of long chains of monomers that form covalent bonds among themselves and with other molecules. The most common chemical systems or types of plastics used in the manufacturing of film include polyethylene, polycarbonate, polystyrene, polyvinyl chloride (PVC) and polyoxymethylene among others. While the pervasiveness of plastic is readily recognized in everyday life, plastic film applications are often overlooked.

Some of the most common uses for plastic film include plastic bags, shrink wrap and protective packaging. Building, construction, packaging, agriculture, aerospace, automotive, electronics, food processing, semiconductor, marine, medical and military industries employ film in these contexts on a daily basis. Additional applications for this versatile material include wood coating, crop and seed protection, dry-wall coating and curing blankets for concrete.Most often used for moisture and environmental resistance, film can be treated to provide anti-static control in order to prevent the build up of energy, protection against electrostatic discharge and electromagnetic interference, flame retardant and dampening. It is important to consider the capabilities of a specific plastic film with regards to its intended use. Plastic film manufacturers can also significantly alter the characteristics and usability of the film by using a variety of different fabrication techniques.

While casting, winding and sheet extrusion are commonly used to produce plastic film, blown film extrusion is the most popular for many applications. In this process the chosen polymer mix is compacted and heated to its flow point, at which time it becomes a viscous fluid. The molten polymer is extruded through a die producing a tube of plastic.

A hole in the center of the die forces air into the enclosed tube. Uniform pressure is applied allowing the air to inflate the plastic at a constant rate creating an even thickness. As the bubble expands upward, a cooling ring slowly lowers the temperature, returning the fluid to a plastic state. At the point of solidification, nip rollers collapse the bubble and flatten it.

The film may pass through a treatment center at this point if any of the aforementioned treatments are desired. While the film is then ready for handling, plastic film manufacturers will usually wind the film with uniform tension for easy transport. In addition to treatments, additives such as heat stabilizers, lubricants, fillers and plasticizers may be added to the raw materials utilized in fabrication in order to improve the physical and mechanical properties of the end product.

These can have a significant impact on the color, strength, density, working temperature range, structural integrity and corrosion and heat resistance of a polymer.

Die Cutting

Die Cutting Foam Fabricating

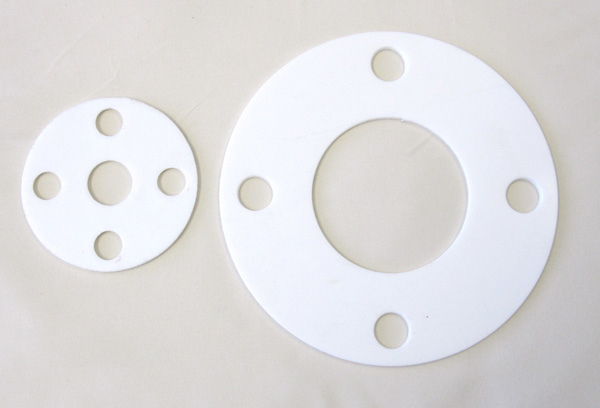

Foam Fabricating Gaskets

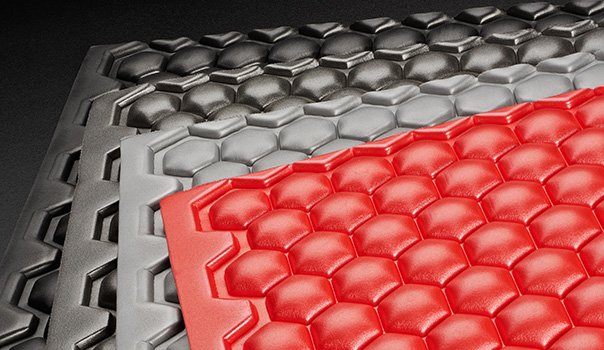

Gaskets Plastic Fabrication

Plastic Fabrication Plastic Materials

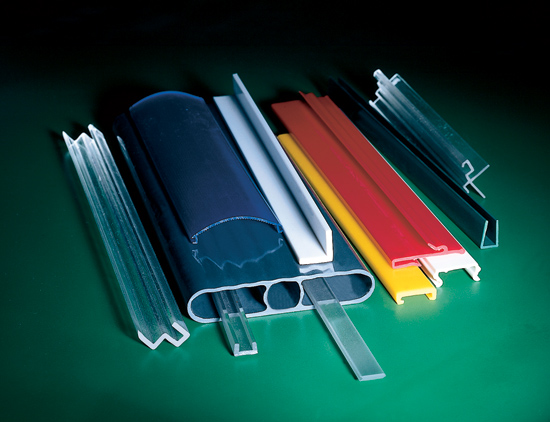

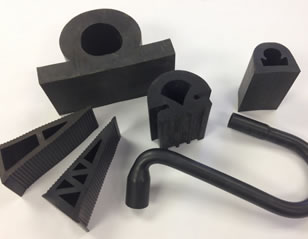

Plastic Materials Rubber Extrusions

Rubber Extrusions Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services